Execution for unbound and bound base layers

Unbound execution

In the case of an unbound execution, the earth anchor can easily penetrate into the base layer through the bedding. After the installation, the vibration procedure is conducted. The shifting prevention device (earth anchor) is then permanently anchored firmly in the superstructure. In this way, the acting dynamic forces can be removed without damage from the earth anchor into the superstructure.

Natural stone/sides sawn!

A complete row always forms a thrust bearing. The rows are repeated several times in hazardous areas. 5-7 rows provide effective protection in hazardous areas. When natural stone material is sawn, there is an increased risk of displacement in traffic load.

Displacement protection is preassembled

The anchor rows are positioned according to the installation plan. A deviation from the installation plan is only advisable with the approval of the planning. The construction company should submit a request to register a concern in the event of disregarded shifting prevention devices according to VOB.

Registering a concern

Use the sample letter in the event that no shifting prevention devices have been provided for in the planning for hazardous areas. Protect yourself from claims arising from displacement, joint expansion or even chipping of the edges. A total loss is not excluded!

Installation of the anchoring system in a bound base layer in unbound execution

In order to secure the anchoring of the anchor in a bound base layer, the base layer must be slit open. The anchor is then attached. A non-woven fabric is placed over the bound base layer. Both the bedding and the grouting are created in the same way as in the unbound construction method. The optimum execution is described in the technical documentation and explained in detail.

Note:

Bound base layers are used in the execution of high dynamic traffic loads. Due to the stiffness of the base layer, a deformation in the superstructure should be prevented. However, the selected slabs or paving are stressed to a large extent during thrust. Shifting prevention devices are especially important in these cases.

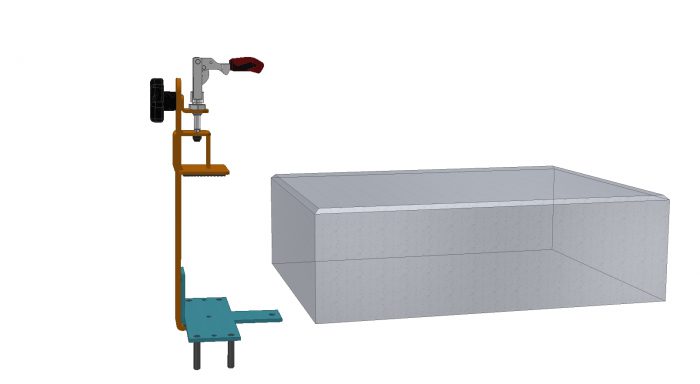

New installation method by means of tools from the company Optimas Maschinenfabrik H. Kleinemas GmbH:

For more information, please see the Downloads section.